Case Study on Productivity (Part 1) – Henry Ford and the Model T

Objective

Students will be able to :

- Describe how Henry Ford’s Model T assembly line increased productivity and lowered production costs in the auto industry.

- Design a simple assembly line.

- Examine the benefits and costs of using an assembly line to produce a good.

In this economics lesson, students will create an assembly line to learn how specialization increases productivity.

Prodedure

Warm-Up

Distribute to each student: 1 6’’x2” piece of card stock, 1 12” piece of string, and 1 marker (or students may use their own pens). Make available (one for every six students): scissors, hole-punch, glue stick, ruler.

Open the PowerPoint Slides and show on a projector screen. Show slide 1 and ask students to each make a bookmark like the one pictured. Explain that they will have about 5 minutes to make the bookmark. Students will likely ask if they have to draw the car. Explain that they should draw it to the best of their ability, acting as artisans. When about half of the students have completed bookmarks, record the time and ask students to stop. Examine a few of the bookmarks and point out any flaws, like poorly drawn cars, missing holes (or holes in the wrong place), missing string, sloppy writing.

Ask students:

- How many bookmarks do you think you could make in an hour?

- Do you think your bookmarks would be of consistent, high quality?

- What would make it easier to produce more bookmarks of consistent high quality in an hour?

Modeling

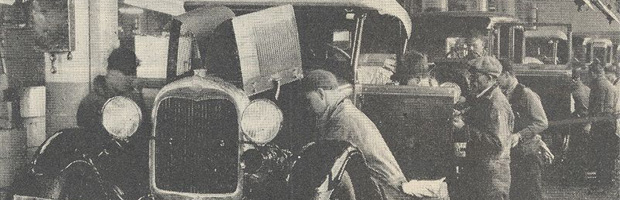

Show slides 2-3. Use the speaking notes in the PowerPoint for talking notes and instructions to your class. Show slide 4, which includes an embedded YouTube video FORD – History of the Model T. Start at 8:45. Stop the video at 13:06. Ask students the questions about the video clip found on slide 5. Wrap-up this section by reviewing slide 6. Use the speaking notes to help with closing remarks.

Group Activity

Explain to students that they are going to make bookmarks again, but this time they will work in a team of [6-8 students, depending on class size] and create an assembly line. Assign students to teams (or let students choose), and provide each team with the following: Assembly Line Flowchart, 2 copies of Assembly Line: Antique Car Image, cardstock paper (several 8-1/2×11 pages), a ball of string, ruler, glue stick, two scissors, hole punch, pencil, marker. Show Slide 7, which provides the specifications for the bookmarks.

Ask students: What is different this time, compared to the original simulation?

Answer: The antique car pictures are provided as an interchangeable part; the card stock and string are not pre-cut; they can work in teams rather than do all the tasks themselves, none of the tasks require creativity.

Ask students to take a few minutes to plan their assembly line, using Assembly Line Flowchart. The black boxes with arrows represent the “main line.” The gray boxes to the side are for the production of intermediate parts, such as cutting out the cars. Students may add boxes, and they may leave boxes blank. Each worker’s role should be in one box. Explain that they must produce their bookmarks consistently, using the measurements provided on Slide 5. A Sample Assembly Line Flowchart is provided to help the class develop a process. Distribute copies to students and/or use this as a supporting material for groups who are struggling with the process.

Remind students that it took the typical student about __ minutes to produce a bookmark in the Warm-Up Activity. Ask students to predict how many bookmarks their team can make in 10 minutes, using their assembly line process. Answers will vary. If each student could produce 1 bookmark in about 5 minutes alone, they should be able to produce more than 2 per team member with an assembly line in 10 minutes. They no longer have to draw the cars, but they do have the added rote tasks of cutting the card stock and string.

Give students 10 minutes to make bookmarks with their teams. Circulate to ensure that students are following the specifications on Slide 5. Each bookmark should be 6”x2”, with a hole cut ½” from the side and 12” string tied through the hole. The antique car should be neatly glued about ½” to the right of the hole. 6. After 10 minutes, ask students to put down their tools and stop working. Ask each group to count how many bookmarks they made. Show slide 8 to report out production calculations. Show slide 9 to debrief the activity with questions and use the speaking notes to review possible answers.

Ask students: What changes have been made to automobile assembly lines since the advances Henry Ford introduced 100 years ago?

Answer: The use of robots, computers, high-tech equipment, 3-D printing, CAD drafting

Explain that over time, American automakers have introduced more and more capital to their assembly lines. They now use fewer – but higher skilled – workers. In China, where labor is cheaper, automakers still rely more on human labor.

Show Slide 10 and play the embedded YouTube video How the Tesla Model S is made. Use the speaking notes to address questions to the class. Show Slide 11 and fast forward to where you left off in the Ford video (13:06). Play the video 13:06 to 14:30. Use the speaking notes for more discussion points.

Assessment

Play the Kahoot! Game with your class. Divide the students into teams or play using 1-1 devices.

Extension

Activity 1

Provide each student with a copy of Assembly Line Flowchart. Ask them to create their own flowchart for an assembly line to produce a product they are familiar with. For example, they could produce a flowchart for lemonade or peanut butter and jelly sandwiches.

Activity 2

Ask each student to write a 250-word response to the following question:

Assuming your wage would be double the current federal minimum wage, would you take a job working on an auto assembly line? Encourage students to list the pros and cons of working in a factory. In addition, students may wish to do online research, looking for assembly-line workers comments about the benefits and costs of their jobs. Some worker testimony is available on Quora at What’s it like to work at an assembly line factory?

Resources

Miscellaneous Items

- cardstock paper (several 8-1/2×11 pages)

- a ball of string

- ruler

- glue stick

- two scissors

- hole punch

- pencil

- marker